The activity of Gelli was established by Gianfranco Gelli in 1976 when he started his own homonymous one-man-business as professional welder. Over the course of the years his firm increased both its size and the offered services. Actually Gelli works on an area of about 40.000 m2, of which over 10.000 m2 completely covered and with state-of-the-art manufacturing facilities for sheet metal working and for the realization of industrial carpentry customized products more or less complex.

OUR PROVIDED SERVICES

EQUIPMENTS

We work with state-of-the-art systems and equipment in all our stages of production, ensuring our customers the best quality.

HOW WE

WORK

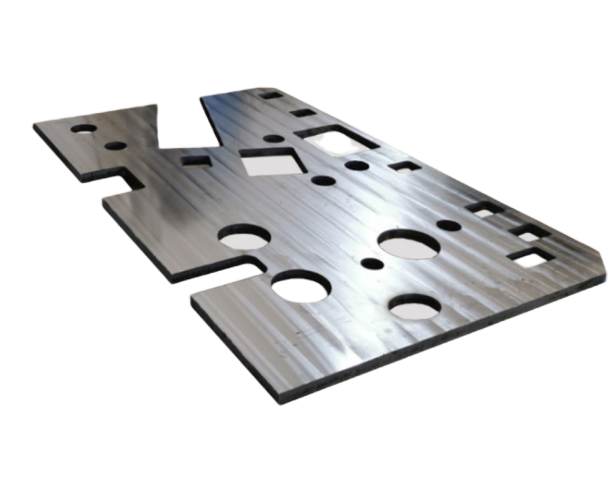

We supply customized laser cutting items, and furthermore we produce bended and welded plates.

In order to supply to our customers a fully finished carpentry product, we cooperate with qualified independent companies for different works such as turning and milling, painting, zinc-coating, thermal treatments, various surface treatments.

We are able to supply to our customers the simple laser cut plates, such as parts more or less complex, up to the complete carpentry of the machinery.